Description

Applied Measurements Torque Meter System is a complete, on-site torque tester system. It is supplied ready calibrated, to UKAS traceable standards, with a 7 digit LCD high accuracy meter, enabling you fast, portable, torque monitoring.

The reaction / static torque transducer DTD-S has a square drive and is designed to measure the fastening or breakaway torque of bolts and nuts. Plus, this torque tester system is ideal for calibrating automated torque screwdrivers, spanners and wrenches.

Thanks to the high accuracy of the static torque transducer of better than ±0.1% of rated capacity, our torque meter systems are perfect for the calibration or testing of torque tools in a QA environment.

The torque meter system has an IP65 dust-tight and splash-proof protection as standard making it suitable for most industrial environments. What’s more, the torque transducer can be customised with improved sealing up to IP68 submersible for applications where operating conditions are harsh or involve long-term submersion.

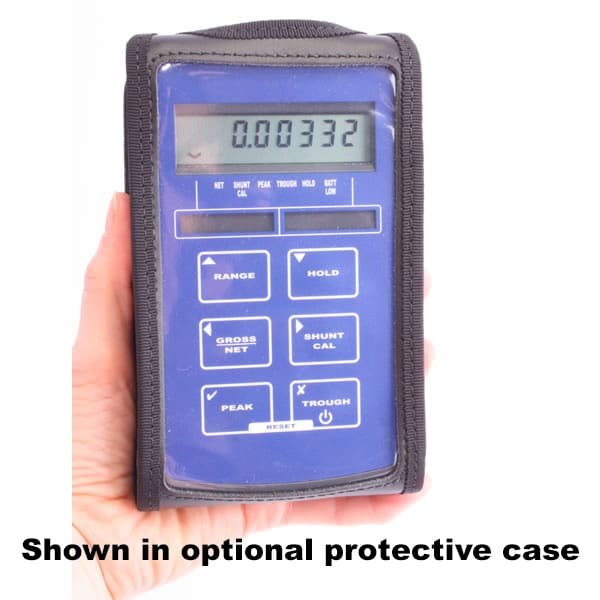

The torque meter system comes with a high resolution 7 digit LCD meter and is protected to an IP65 dust-tight, splashproof rating. It features peak & trough capture at 25Hz, display update rates up to 10Hz, display hold/freeze, shunt calibration and optionally an RS232 serial data output.

The digital meter’s dual-range capability means it can be calibrated in 2 separate engineering units (i.e. Nm and lb-ft) or it can be calibrated with 2 separate torque transducers.

Need an integrated torque meter and display? Try our DRBK-A Low Cost Rotary Torque Sensor with Display which features a built-in 4 segment LCD display giving you instant torque and speed readings with real-time speed updates of 1x sample/second and torque updates of 1,000 sample per second.